Putting distance between you and danger

In hazardous environments people are at risk. Those hazards however are not always well understood by everyone. An example would be shutting off a fuel line. Sounds simple. Now imagine that fuel line is under a train, hard to reach and needs to be approached in an awkward way. Can the train move? Perhaps not, but sometimes they do.This is a real-world problem, that we solved for a fleet of trains.

Valves and other devices, while installed for good reasons, are not always easy to reach and operate.

In the case of the trains, generator sets under each carriage provided power for air conditioning, lighting and so forth. An engineering analysis discovered that the routing of fuel lines between the fuel tank and the generator set under each carriage would sometimes create air bubbles in the fuel, those built up, starved the generator set of fuel, eventually leading to an auxiliary power out. So, no lights, no air, and no opening of doors.

The re-routing of the fuel line solved that problem but created another. In maintenance work the fuel had to be shut off manually to ensure safety. The fuel shut-off valve was now under a train, difficult to reach (or even see) or operate.

What to do.

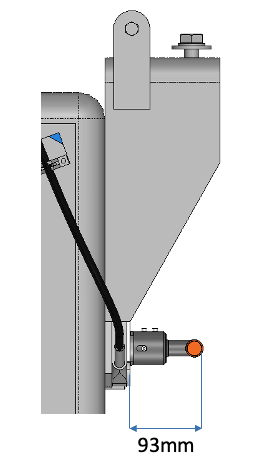

Flexible Drive designed and created a remote valve controller. The valve was still under the train, but the control lever was now outside on the side of the train carriage, easy to reach, intuitive to operate, lockable, and as a mechanical system, did not require power eliminating a fire hazard (certain fuels and power are not a great combination).

The same principles apply to many other situations. Our Aktivo Safety Remote Valve Operating system is now being used in transport applications such as tankers to operate high valves or valves located under the tank. The system is easy to install, flexible, reliable, and great value when you consider what’s at stake (your operators). Our system offers:

- 3, 4 or 6-inch(150mm) Stroke/Travel

- Locking feature

- ¼ or M6 connections

- Clamp of bulkhead connections

- Custom Lever length to maximize load capacity and stroke

- Custom gate plate design

- Load Table. Crack Torque relative to load, stroke, lever length

|

Minimum bend radius |

Max Pull load |

Max Push load for |

|||

|

|

|

2 Inch stroke |

3 inch Stroke |

4 inch Stroke |

|

|

200mm |

1467N |

685N |

587N |

489N |

|

We pride ourselves in our approach to service and can assist you with designing a suitable system for your unique challenge. Just ask us.